PAGE 1 OF 9

Last revised: 10 September 2009

POLARIS—POSEIDON---TRIDENT

AN AWESOME

CONCEPT

SEA-LAUNCHED BALLISTIC MISSILE SYSTEMS

GENERAL ELECTRIC---UNITED STATES

NAVY

============ A TUTORIAL ADVENTURE

IN HIGH TECHNOLOGY ==========

A

story about General Electric, Charles Wright and ICBM (missile) systems.

At Charleston SC, during the Cold War era, the most terrible

weapon that had ever been devised came into existence----General Electric

helped develop and build it. It was the submarine-based Inter-Continental

Ballistic Missile System----or just Polaris (named in honor of the North Star).

It was the single most-important national venture at the time---even above

Apollo----because the capability for hiding mobile nuclear missiles in the

vast oceans of the world would absolutely guarantee our nation’s

supremacy. As an engineer, I

consider myself fortunate to have taken part in this major state-of-the-art

military venture. Each original-design

missile was about 28 feet long (weight 30,000LB). See Page 4. Most

of it was made up of a solid-fuel rocket engine, about 4.5 feet in diameter. The

guidance system of each missile was about the size of the average

commode---the computer being the tank and the rest of the commode being the

gyro portion (call it the Analog portion). The Analog portion had

three gyros and 3 accelerometers mounted in a chunk of metal (about the

size of a half-gallon milk carton---with cutouts to hold these 6 cylindrical

devices). Each gyro and each accelerometer was about the size of a small can of

soup. The chunk of metal was

mounted via ball bearings inside of a square frame (about like a square,

deep picture frame). And that frame was mounted at right angles inside

another slightly bigger square frame via bearings---this bigger frame was

connected to the outside body of the guidance system by more ball

bearings. This arrangement allowed the inner chunk of metal to

rotate around in any angular position imaginable (but, in use, it actually remained “fixed”, angularly,

and the rest of the missile revolved about it). These frames were

called gimbals and the inner chunk of metal (holding the gyros and

accelerometers) was called an inertial platform. (it was called

“inertial”---which means “fixed” because it never moved angularly in space

after it was initially positioned, even though the entire missile might be

making various angular movements around it while traveling to a target). The

whole Analog portion (with gyros and accelerometers on the inertial platform,

and the gimbals) was about twice the size of a basket-ball. See

Appendix for a picture. Of course,

the guidance system (the whole “commode”) was bolted to the overall missile

frame. GE built these guidance systems at its Pittsfield, Mass. plant-----a

technical wonderland of electro-mechanical engineering. It was a vast operation-----and it had

an additional 400 engineers and technicians out in the field.

At Charleston SC, during the Cold War era, the most terrible

weapon that had ever been devised came into existence----General Electric

helped develop and build it. It was the submarine-based Inter-Continental

Ballistic Missile System----or just Polaris (named in honor of the North Star).

It was the single most-important national venture at the time---even above

Apollo----because the capability for hiding mobile nuclear missiles in the

vast oceans of the world would absolutely guarantee our nation’s

supremacy. As an engineer, I

consider myself fortunate to have taken part in this major state-of-the-art

military venture. Each original-design

missile was about 28 feet long (weight 30,000LB). See Page 4. Most

of it was made up of a solid-fuel rocket engine, about 4.5 feet in diameter. The

guidance system of each missile was about the size of the average

commode---the computer being the tank and the rest of the commode being the

gyro portion (call it the Analog portion). The Analog portion had

three gyros and 3 accelerometers mounted in a chunk of metal (about the

size of a half-gallon milk carton---with cutouts to hold these 6 cylindrical

devices). Each gyro and each accelerometer was about the size of a small can of

soup. The chunk of metal was

mounted via ball bearings inside of a square frame (about like a square,

deep picture frame). And that frame was mounted at right angles inside

another slightly bigger square frame via bearings---this bigger frame was

connected to the outside body of the guidance system by more ball

bearings. This arrangement allowed the inner chunk of metal to

rotate around in any angular position imaginable (but, in use, it actually remained “fixed”, angularly,

and the rest of the missile revolved about it). These frames were

called gimbals and the inner chunk of metal (holding the gyros and

accelerometers) was called an inertial platform. (it was called

“inertial”---which means “fixed” because it never moved angularly in space

after it was initially positioned, even though the entire missile might be

making various angular movements around it while traveling to a target). The

whole Analog portion (with gyros and accelerometers on the inertial platform,

and the gimbals) was about twice the size of a basket-ball. See

Appendix for a picture. Of course,

the guidance system (the whole “commode”) was bolted to the overall missile

frame. GE built these guidance systems at its Pittsfield, Mass. plant-----a

technical wonderland of electro-mechanical engineering. It was a vast operation-----and it had

an additional 400 engineers and technicians out in the field.

The way the missile system worked was as follows. When the rocket engine burns, it blows hot

gasses out of the back of the missile, pushing the rocket up through the

sky and space to its target. These gasses are forced to go out

through 4 short pipes (nozzles) called "jetavators." In flight, the

jetavators can be turned slightly---by the guidance system computer---in any direction

so that the back of the missile can be turned (guided, steered) toward the

target. In order for the guidance system to "keep its

balance" the gyros must keep the inertial platform (the inner chunk of

metal) from moving angularly as the missile is maneuvered through the sky

(something like the little sensors in your head help you keep your

balance). Before the missile is launched, the inertial platform is set to

a given angular position; then, as the missile maneuvers, after launch, the

gyros sense if the platform starts to tilt from its pre-set position,

and---by electric motors(operating in servomechanism loops)---

PAGE 2 OF 9

force the gimbals to turn back, to keep the platform where

it was originally set, angularly (in inertial space---the residual space in

which the Earth exists). Transformer-like electronic devices (called

resolvers) that measure angles, are located at each of the gimbal bearings, to

tell the computer how much the missile has turned in every direction around the

fixed inner inertial platform. This allows the computer to

know exactly how the missile is pointed. As stated, the inner

platform also has 3 accelerometers mounted on it to keep the computer informed

(by sensing motion) as to just how far (and how fast) in every direction the

missile has traveled since it was launched.

So the computer "knows" exactly where the

missile is at all times, and how it is pointed. Since the computer was

"told" where the missile is intended to go, the computer can actuate

the jetavators to keep the missile on the course that was mathematically programmed

into the computer before launch. When the computer decides that the

missile is going at the correct speed and is pointed in the right direction so

that the warhead (like a rock being thrown) will hit the target, the computer

cuts the warhead loose and allows it to hurtle through the sky to hit the target. At that time, the rocket engine is

shut off and it and the guidance system fall to earth as expensive

junk.

When I started working in the Polaris program, I was

told that each guidance system cost a quarter of a million dollars.

They were so valuable and secret that an engineer (courier) slept alongside

each one (in a sleeping bag) on a cargo plane (I did it a few times) as the

guidance system was being shipped from Massachusetts to the Lockheed plant in

California------the guidance system had to be kept inside a sealed container

at an exact temperature (the engineer had to manually wire into the

plane's electrical system to get power for the container). I was assigned

as a courier a few times so that I could write detailed procedures for other couriers

who would do it regularly. Even that was a small adventure.

This

guidance system----conceived by MIT, with a digital computer and an inertial

section ---was so complicated that

very few people ever understood it. As a small example,

consider that the tiny gyro rotors in the gyros and accelerometers were (each)

turning at 16,000 RPM in a sphere (about the size of a golf ball) that was precisely

suspended in a magnetic field, so that precession bearing friction would be

eliminated. SEE

APPENDIX. I was lucky enough to be

the Guidance System Specialist at Charleston SC where about 40 GE engineers

had an office on the Polaris missile base---officially named Polaris Missile

Facility, Atlantic (POMFLANT). The massive office building also

housed the base commanding officer, about 125 employees from Lockheed (the

missile prime contractor) and about 10 from Aerojet-General (the rocket-engine

supplier), along with myriad Civil Service engineers and naval officers. There were about 900

people---contractors, Civil Service and Military---working at POMFLANT.

The

guidance systems had to be tested and calibrated at this base before they were put

into missiles and into the submarines at Charleston. Each

guidance system was not perfect---it had errors in its gyros and accelerometers

that could make the missile miss its long-range target. Therefore we had to determine exactly

what these errors were---e.g., like the speedometer on your car being in error

by a few miles per hour. We would

carefully measure gyro and accelerometer errors so that the submarine could

take them into account and offset them before the missile was launched.

As a vastly-oversimplified

example, if the guidance errors would cause the missile to hit 10 miles to the

left of the target, the submarine would apply factors to aim it 10 miles to the

right. Six-to-eight hours were

required to calibrate and test each guidance system----the intricacies involved

were staggering. GE also built all

the large test/calibration consoles and nearly all other support

equipment----including the main missile-control consoles for the

submarines.

There

were 16 missiles on each submarine. It was stated that each submarine was

more powerful than all the bombs dropped by everyone (both sides) during

World War II, including the atomic bombs dropped on Japan. It was an

awesome feeling to be there, working about a block from countless atomic

bombs (stored in the warheads).

PAGE 3 OF 9

The

base was about 5 miles in diameter and it had a highly-secret inner base

about a mile in diameter. The inner high-security base is where the

missiles, warheads and guidance systems were kept and tested. There were

armed marine guards everywhere---it was a bit scary. The inner base was

surrounded by deep swamps (even swamp panthers prowled around the wild area---I

have seen them at night when I had been working late). My job was

to be an expert on the "brains" (the guidance system) of the missile

and to keep track of and report-on reliability problems and trends---and (using

all the metric data being recorded as guidance systems were processed) write

secret missile statistical-accuracy reports (CEP) for Admiral W. Raborn (later, Admiral L.

Smith and Admiral I. Galantin) who was at Washington---he was in

charge of the program nationwide for the Navy. The program was completely controlled by the Special

Projects office at WashDC. Key

people were identified by codes----I was SPC91 (Special Projects Charleston #91). All contractors and civilians on the

base were under the technical control and auspices of a Civil Service Chief

Engineer and his supporting staff----this provided continuity and it prevented

chaos.

The

other electronic equipment---associated with the missile system----at the

Charleston base and on the submarine, would take one person 2 lifetimes to

learn. I was closely involved with just one little part of it all---the

guidance system (but that was the most complicated and most interesting part of

the missile). The Guidance System Laboratory Building was 200 X 200

feet, 2 stories high, and was located on the inner security base.

In

a (separate) Missile Assembly Building, each entire missile was laid

horizontally in a berth and checked completely with a guidance system intact

before being released to the Navy.

GE, having a major role in the Polaris program, was involved in

developing extensive documentation for myriad formal instructions, along with

intricate quality control and trouble-shooting measures. EVERYTHING had to be documented

in great detail. Further, GE

maintained a large school facility at Pittsfield for Navy personnel and GE

engineers and technicians. Almost

everything was in a state of cutting-edge development-----sometimes I would

need to interface directly with the scientists at MIT to resolve guidance

system technical issues.

I

would often travel to Massachusetts, Connecticut, and California on business

associated with my job (being away sometimes for 3 months). In all, it

was a fantastic experience, actually breath-taking. I

felt at home as a civilian working on naval bases because I understood the Navy

way (I had spent many years in the active

air Navy and I was still a reserve naval officer, going for air-squadron duty

each month and 2 weeks of every year)---some people could not adapt and

work well with Navy personnel.

I

eventually became GE’s Engineering Supervisor at Charleston-----my group was

responsible for everything technical associated with GE’s role at the

missile facility, including reliability reporting and special investigations, aforementioned

statistical missile accuracy reports, training classes for our local engineers,

technical requirements for new buildings and a vast amount of test and

calibration equipment (and also for interfacing with other contractors who

built the rest of the missile hardware).

GE had two other groups of personnel at the base------one administrative

group to help the Navy with logistics; and a technical group to melt-in with

Civil Service and Navy people who were in long-term training to eventually take

over the test/calibration functions at the inner base.

While

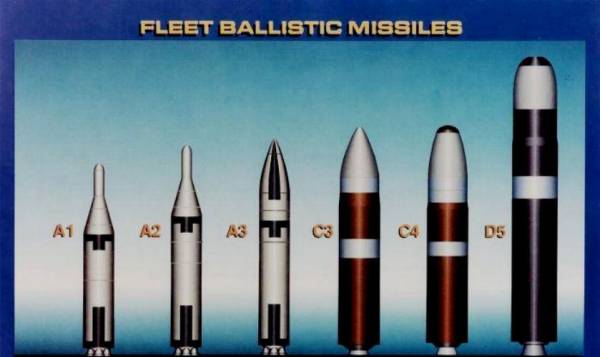

I worked at Charleston, the overall A1 Polaris system underwent 2 complete

re-designs, A2 and A3 (with a smaller, lighter, improved guidance system) to

increase the range from 1200 NM to 2500 NM. It then began being supplemented by a bigger and better

missile system---called Poseidon (god of the deep). Its guidance system actually

tracked a distant star to help keep its inertial platform fixed more accurately

all during flight. Poseidon was much more awesome and more powerful

than Polaris. I worked in the Poseidon engineering program for a while, and

then moved to Daytona Beach to embark on another adventure----the Apollo

man-on-the moon project. A previous GE manager had transferred to

that program and invited me to work with him in Florida. I’ll tell you that Apollo story later.

PAGE 4 OF 9

After I left Charleston, the

completely-awesome Trident Missile submarines became the next generation---they

are in use today. GE also played a

role in their deployment.

![]()

YEAR 1960 1962 1964 1971 1972 1982

LENGTH (FT) 28.5

31.0

32.3

34.0 34.0

44.6

DIAM (IN) 54

54

54

74

74

83

WEIGHT (LB) 30,000

32,500 35,700 85,000

> 85,000 > 120,000

RANGE

(NM) 1200

1500

2500

2800 > 4000 > 4000

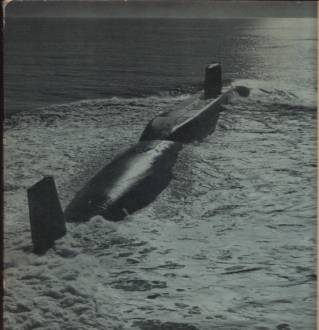

TRIDENT C4 LAUNCH

It is interesting to note

that the rocket engine of each of these submarine-launched missiles---Polaris,

Poseidon and Trident---is not ignited until it is above the sea surface. The missile is burped out of its

submarine launch tube by compressed gasses, flinging it out of the water. Even though this jerks the

missile around violently, the guidance system senses and records all velocity

movement and keeps its inertial platform fixed. Wow!

PAGE 5 OF 9

POLARIS MISSILE BEING

LAUNCHED AT SEA

AS SOON AS WE FELT

REASONABLEY CONFIDENT, WE FIRED A TACTICAL POLARIS MISSILE FROM THE SUBMERGED

SSBN ETHAN ALLEN TO A LOCATION 1700 MILES AWAY IN THE PACIFIC-----IT CARRIED A

LIVE NUCLEAR WARHEAD THAT EXPLODED EXACTLY ON TARGET. THIS PROVED THAT THE ENTIRE SYSTEM WORKED WELL----AND

IT GAVE THE USA A GIANT ADVANTAGE IN THE COLD WAR WITH RUSSIA.

POLARIS WAS AN

ABSOLUTELY ASTONISHING ENGINEERING ACCOMPLISHMENT. ITS PROGRESS WAS

BASED ON JUST-IN-TIME TECHNICAL DEVELOPMENTS-----IT ALL CAME TOGETHER

MIRACULOUSLY AS IF A DEVINE HAND WERE GUIDING IT. THEN POLARIS SET THE STAGE FOR ADVANCEMENTS TO THE POSEIDON

AND TRIDENT MISSILE SYSTEMS. I WAS THERE NEAR THE BEGINNING PHASES OF POLARIS

DEVELOPMENT----IT WAS AN AWESOME FAST-MOVING ADVENTURE. IT HAD TOP PRIORITY IN

EXPENDITURES FOR DEFENSE OF THE UNITED STATES. SUCCESS OF THE POLARIS PROGRAM WAS DUE MAINLY TO

THE MANAGERIAL LEADERSHIP OF ADMIRAL WILLIAM RABORN AND THE NATION’S GREATEST

UNIFORMED SCIENTIST, CAPTAIN (LATER ADMIRAL) LEVERING SMITH. WHEN THE FIRST SUCCESSFUL POLARIS WAS

LAUNCHED FROM THE SUBMERGED SSBN GEORGE WASHINGTON, RABORN SENT SMITH A PHOTOGRAPH

OF THE RISING A1 MISSILE, WITH RABORN’S PERSONAL GREETINGS WRITTEN ON THE

PICTURE----AFTER ADMIRAL SMITH DIED, THAT PICTURE WAS SENT TO ME BY THE MANAGER

OF SMITH’S ESTATE. I

TREASURE IT AS AN HISTORICAL AND SCIENTIFIC TOUCHPOINT.

PAGE 6 OF 9

TRIDENT ACTUALLY HAS A RANGE

EXCEEDING 4,000 MILES

A BALLISTIC MISSILE SUBMARINE

PAGE 7 OF 9

=

ANOTHER

VIEW OF A BALLISTIC MISSILE SUBMARINE

==============

POST SCRIPT==============

AFTER WE HAD JUST LOADED

THE FIRST POLARIS SUBMARINE WITH 16 MISSILES, MY COLLEAGUE SAID, “CHARLIE; I

KNOW THAT YOU REALIZE THE OMNIPITANT POWER OF THE WEAPON SYSTEM THAT WE HAVE

TURNED LOOSE IN THE WORLD.

HOW CAN WE JUSTIFY HAVING DONE SUCH A THING?” I COULD ONLY

ANSWER THAT I HAD GENUINE FAITH THAT MY GOVERNMENT WOULD NEVER USE THAT AWESOME

POWER EXCEPT AS A DETERRENT, OR AS A WEAPON OF LAST RESORT. BEING A NAVAL OFFICER----READY

RESERVE AT THE TIME---AND KNOWING THE MEN WHO MANNED THESE SUBMARINES,

I ALSO FELT THAT I COULD TRUST THEM COMPLETELY.

PAGE 8 OF 9

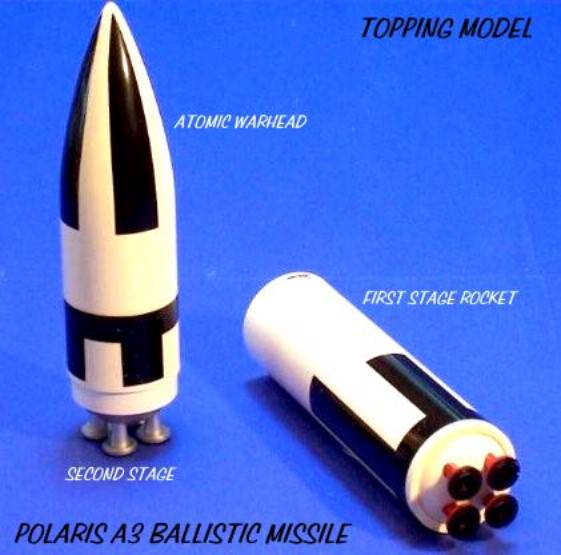

TOPPING WAS A FAMOUS COMPANY THAT BUILT ALL KINDS

OF MODELS FOR THE GOVERNMENT AND FOR INDUSTRY.

PAGE 9 OF 9

THE CIRCULAR EMBEDDED-BRASS WRITING ON THE BASE SAYS

POLARIS == THE FREE

WORLD’S PRIME DETERRENT WEAPON SYSTEM

SEE

APPENDIX

==================

END OF MAIN FILE ===================

BEGIN APPENDIX

NOTE THAT

EACH MARK-1 GUIDANCE SYSTEM IS RESTING ON TWO RAILS.

THERE ARE

ALSO RAILS IN THE MISSILE SO THAT THE GUIDANCE SYSTEM CAN

BE READILY

PULLED OUT AND REPAIRED----OR BE REPLACED BY ANOTHER ONE.

EVEN

IN STORAGE, THESE SYSTEMS WERE NEVER WITHOUT POWER. THE GYROS AND ACCELEROMETERS ON THE INNER GIMBAL CONTAINED A

VISCOUS (THICK) FLUID

CALLED

FLUROLUBE THAT HAD TO BE MAINTAINED AT AN EXACT TEMPERATURE.

THIN

WIRES, ABOUT LIKE A HUMAN HAIR, CARRIED POWER THROUGH THIS FLUID

TO

THE TINY GYRO MOTORS THAT WERE HOUSED INSIDE TINY SPHERES. THESE SPHERES (about the size of a golf ball) WERE MAGNETICALLY

SUSPENDED AND WERE SURROUNDED BY THIS FLUID TO PROVIDE A DAMPING FUNCTION IN

THE SERVO MECHANISM LOOPS OF THE GYROS AND ACCELEROMETERS.

WHAT HAPPENS IN A

SERVOMECHANISM LOOP IS SOMETHING LIKE WHAT HAPPENS WHEN YOU ARE

DRIVING A CAR. A SENSOR

(your eyes) DETECTS THAT THE CAR IS GETTING TOO FAR TO THE RIGHT; YOUR EYES SEND A SIGNAL TO YOUR BRAIN;

YOUR BRAIN TELLS YOUR HAND TO TURN THE CAR BACK TO THE LEFT, POSITIONING THE

CAR WHERE IT SHOULD BE ON THE ROAD.

LIKEWISE-----THE POLARIS

GYROS SENSE THAT THE “FIXED INNER GIMBAL” OF THE GUIDANCE SYSTEM HAS SLIGHTLY

MOVED; THE GYRO INSTANTLY SENDS A SIGNAL TO A MOTOR WHICH FORCES THE INNER

GIMBAL BACK WHERE IT WAS ORIGINALLY POSITIONED. THREE DIFFERENT GYROS DO THIS CONTINUALLY IN 3 DIRECTIONS TO

KEEP THE INNER GIMBAL ABSOLUTELY FIXED ANGULARLY. THEY DO THIS SMOOTHLY JUST LIKE YOU SMOOTHLY KEEP YOUR CAR

IN THE RIGHT LANE WITH MINUTE MOVEMENTS OF THE STEERING WHEEL. THE THICK FLUROLUBE FLUID HELPS THIS

GYRO ACTION TAKE PLACE SMOOTHLY.

THIS PICTURE SHOWS THE MAMMOUTH SIZE OF THE A3 POLARIS

MISSILE, AS

COMPARED

TO A

MAN. IMAGINE THE SIZE OF A

SUBMARINE

THAT

CARRIES SIXTEEN OF THESE MISSILES,

THEN

IMAGINE THE

SIZE OF THE

TRIDENT

SUBMARINE

THAT CARRIES SIXTEEN EXCEPTIONALLY-

LARGER

MISSILES.

THIS IS A

MODEL OF THE POLARIS INERTIAL PLATFORM. IT IS USED BY TEACHERS TO DESCRIBE INERTIAL GUIDANCE

SYSTEMS FOR MISSILES AND SPACECRAFT.

THE WHITE

CHUNK IN THE MIDDLE IS THE PLATFORM UPON WHICH IS MOUNTED THREE (RED)

ACCELEROMETERS AND THREE (WHITE) GYROS.

THE CHUNK CAN ROTATE HORIZONTALLY ON BEARINGS AT ITS TOP AND

BOTTOM. THE SILVER RINGS ARE CALLED GIMBALS AND THEY CAN MOVE IN ANY

DIRECTION ANGULARLY. THE

BLACK FRAME AND THE BASE REPRESENT THE MISSILE BODY. WNEN THE

WHITE CHUNK IS ALIGNED WITH A TARGET, IT NEVER MOVES AGAIN ANGULARLY---IT

REMAINS INERTIAL (FIXED ANGULARLY).

AS THE MISSILE BODY TWISTS AND TURNS TOWARD THE TARGET, THE WHITE CHUNK,

THE STABLE PLATFORM, REMAINS

FIXED---SO THAT THE ACCELEROMETERS AND GYROS STAY ON THEIR COORDINATE SYSTEMS

IN SPACE. RESOLVERS EXIST AT THE

GIMBAL BEARINGS TO CONTINUOUSLY MEASURE THE ANGLES OF THE GIMBALS RELATIVE TO

EACH OTHER AND TO THE MISSILE BODY.

THUS, THE GUIDANCE SYSTEM KNOWS THESE ANGLES, AND THUS KNOWS HOW THE

MISSILE BODY IS POINTED AT ALL TIMES.

THIS IS AN ACTUAL POLARIS GYRO, DISMANTLED. I REMOVED THE

GYRO WHEEL (upper center) THAT SPINS INSIDE THE TINY SPHERE.

THE WHEEL’S UPPER BEARING IS STILL ON THE WHEEL. THE SPHERE NOW LOOKS LIKE AN EMPTY

CUP. WHEN THE GYRO IS PUT

TOGETHER, THE “HANDLES” THAT STICK OUT ON THE SPHERE ARE SUSPENDED IN A

MAGNETIC FIELD THAT IS GENERATED BY THE ORANGE DONUT-SHAPED END CAPS. ANOTHER DONUT EXISTS ON THE OTHER END

OF THE CYLINDRICAL CASE. THE SPHERE IS SURROUNDED BY A MOLASSIS-TYPE FLUID THAT

KEEPS THE SPHERE FROM MOVING EXCEPT VERY SLOWLY. THE STICKY FLUID IS CALLED FLUOROLUBE. IT DAMPS MOTION IN THE GYRO’S

ELECTRONIC SERVOMECHANISM LOOP---A SYSTEM THAT KEEPS THE PLATFORM FIXED

ANGULARLY.

HERE IS AN ASSEMBLED

GYROSCOPE UNIT---IT

IS

THE SAME ONE THAT IS

SHOWN

DISMANTLED

ABOVE.

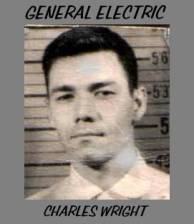

ABOUT THE AUTHOR, H. CHARLES WRIGHT

Mr. Wright was trained as an electronics specialist in the

U.S. Navy to function as a Flight Crewman in Air Anti-Submarine

Squadrons----operating from aircraft carriers and naval air stations to search

for and destroy Russian submarines.

Mr. Wright was trained as an electronics specialist in the

U.S. Navy to function as a Flight Crewman in Air Anti-Submarine

Squadrons----operating from aircraft carriers and naval air stations to search

for and destroy Russian submarines.

After being released from the Navy,

he attended West Virginia University and graduated as an Electronic Engineer.

He immediately was hired by General Electric to specialize in inertial guidance

system technology. General

Electric Ordnance Systems (GEOS)---Pittsfield, Massachusetts---was the prime

contractor for the guidance system of the Polaris Missile.

(GE also

supplied the submarine fire-control consoles; land based GS calibration

consoles; myriad miscellaneous test equipment units; and all associated

documentation)

Mr. Wright was first assigned to

document instructions for those who would be couriers, accompanying secret

inertial guidance systems being transported from Pittsfield to the Lockheed

plant at Sunnyvale, California. At

Lockheed, the guidance systems were, for the first time, interfaced and tested

with Polaris missiles that were being built there. Mr. Wright was a courier himself until this

documentation was completed. In addition to secrecy, the guidance systems

were very fragile, requiring special handling, constant surveillance (during 2

days of travel), plus an interface with electrical power in freight

aircraft. The courier slept in the

plane alongside the large shipping container.

After that assignment, Wright was

sent to the Lockheed plant for three months, to study the guidance system’s construction

and its complex testing requirements. He then went to POMFLANT (Polaris Missile Facility—Atlantic),

Charleston SC, a vast missile base, which was still under construction. His first assignment was to document

the methods for testing and repair of the guidance system’s servo-mechanisms,

power supplies and computer.

Next he was involved in testing and calibration of the overall guidance

system, perfecting related documentation and establishing quality-control

methods. He was also assigned as training coordinator, to educate other

engineers and technicians in the complex details associated with GS testing and

calibration. Guidance systems were not perfect—they had errors that needed to be

quantified so that the Submarine

could compensate with offsets before launching a missile. Wright was also assigned to investigate any GS-related

problem trends that required prolonged study and corrective action. Since the GS interfaced with

other missile electronics, this often involved working with Lockheed engineers

to resolve problems. Mr. Wright

wrote overall reliability reports for all components of the General Electric

guidance system and the guidance systems produced by the Hughes Aerospace

Corporation (the secondary GS contractor). These reports had a wide distribution, including SPO, the

Special Projects Office at WashDC. Additionally, Wright was assigned to periodically

compile all combined GS error data and write Secret statistical reports that

detailed the accuracy of the missile guidance system-----Circular Error

Probability (CEP). CEP showed the

SPO Director what percent of missiles launched would hit targets within a given

radius.

Wright was eventually promoted to

supervise other engineers who were charged with the functions that he had

previously performed. In

this capacity, he was also responsible for GE’s interface with POMFLANT’s Chief

Engineer staff-----and with other contractors; and for guidance-related

facilities-planning associated with Polaris and Poseidon missile systems.

Mr. Wright represented GE by making tutorial presentations

on inertial guidance systems to professional organizations---example: American

Institute of Electrical/Electronic Engineers. Mr. Wright studied servomechanism theory and design at the

local Citadel College. He also

interfaced directly with MIT on GS computer problems and new-accelerometer

design. When Raytheon became a

contractor for GS production, he went there to study their hardware designs. Wright was a single point of

contact at POMFLANT for missile guidance system subjects.

Wright later carried his

Rocket Scientist knowledge into the Apollo space program, where General

Electric played a major role in supporting NASA. He was a consultant to NASA HQ personnel for problems

associated with Apollo Guidance and Navigation Systems and Lunar Module

pyrotechnics

----also conducting studies

on gyro and accelerometer error trends.

[Wright’s missile and spacecraft work spanned a decade of

time]

////////////////////////////////// END OF APPENDIX /////////////////////////////////////